Hydraulic dock levelers

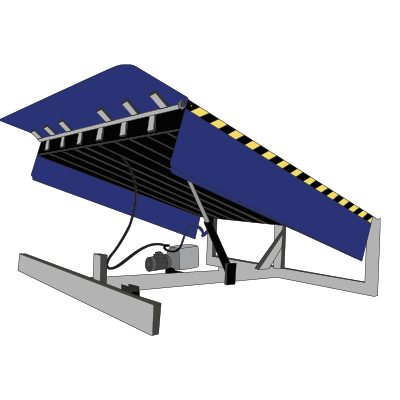

The Alapont standard dock leveler is the solution that is suitable for any loading dock. It is characterized by its strength and safety. It’s the fast, economical and easy way to maneuver in order to overcome the differences in level between the loading dock and the truck bed.

It has a hinged lip that allows the lip to adapt perfectly to the truck. A properly equipped dock leveler can help prevent rapid leveler descent, even while managing heavy loads; it can also help maintain a safe and reasonable slope from the facility floor to the trailer bed while floating below and above dock height.

Standard features

| Load capacity | Up to 30000lbs, 40000lbs, and 50000lbs |

| Power supply | 115 V/1ph/ 60 Hz |

| Consumption | 2A |

| Hydraulic group power | 1,1 kw (1,5 HP) |

| Colour | Standard: GREY RAL 7011 . Possibility galvanized |

All this options can be customized.

Technical features

The main characteristics of Alapont Logistics standard loading docks are:

- The platform is supported by 10 reinforcement beams which provide greater strength and durability. They also withstand the continuous passage of vehicles and therefore prevent the bed of the leveler from becoming deformed.

- All the hinges are reinforced to guarantee maximum strength.

- Please consult for details about the galvanised option.

- We can adjust to any dimensions.

- The hydraulic dock leveler is made of 5/7 steel teardrop plates with one lifting cylinder and a cylinder for the hinged lip, which is composed of 13/15 teardrop plate and has a projection of 400 mm.

- It is treated with an anti-corrosion system and painted with an oven-polymerised powder coating.

- Hydraulic unit powered by a 1.1 kW (1.5 HP) – 115V/ 1ph /60 Hz motor with slow dock descent control in case the truck is leaving. Resistant to temperatures of between -20ºC and 50ºC.

- An electrical control panel with an IP55 water-resistance rating and equipped with an approved emergency stop button.

- Load capacity: up to 30000lbs, 50000lbs, and 80000lbs.

Standard References

*Finishes options: painted and galvanized

| Nominal Model Sizes | Platform Size | Pit specifications | ||||||

|---|---|---|---|---|---|---|---|---|

| Deck width | Total length* | Pit width(W) | Pit length (L) | |||||

| ft | in | mm | in | mm | in | mm | in | mm |

| 6′ x 6′ | 72” | 1830 | 74” | 1890 | 73” | 1860 | 61” | 1555 |

| 6′ x 8′ | 72” | 1830 | 98” | 2495 | 73” | 1860 | 85” | 2155 |

| 6′ x 10′ | 72” | 1830 | 124” | 3140 | 73” | 1860 | 110” | 2800 |

| 6′ x 12′ | 72” | 1830 | 147” | 3725 | 73” | 1860 | 134” | 3390 |

| 7′ x 6′ | 84” | 2130 | 74” | 1890 | 85” | 2160 | 61” | 1555 |

| 7′ x 8′ | 84” | 2130 | 98” | 2495 | 85” | 2160 | 85” | 2155 |

| 7′ x 10′ | 84” | 2130 | 124” | 3140 | 85” | 2160 | 110” | 2800 |

| 7′ x 12′ | 84” | 2130 | 147” | 3725 | 85” | 2160 | 134” | 3390 |

| Pit dimensions | ||

|---|---|---|

| Standard pit depth | Pit to Deck Width | Pit to Deck Lenght |

| Front 20” (508mm) / Rear 19.5” (495mm) | W (pit) = W (deck) + 1” (25,4mm) | L (pit) = L (deck) |

Resources

Hydraulic Dock Leveler Benefits

High Quality

The hydraulic dock levelers with a hinged lip are made of 6/8 mm teardrop steel plate, with one lifting cylinder and another for the lip. The latter is made with 13/15 mm teardrop plate and with a projection of 400 mm. The metal plates are treated with an anti-corrosion system. There is also the possibility of a galvanized finish, thus increasing their durability.

Possibility of designing custom-made dock leveler, adapting to the different characteristics of the dock.

After sales service

At Alapont Logistics USA you have technical advice available before and after the purchase, and maintenance of all the components of your loading docks, thus ensuring your peace of mind and comfort. Our technical service gives you the support you need, either for replacing a part, advising you if you have any questions or simply guaranteeing the good service and use of the loading dock.

High strength and durability

In order to minimize deforming and ensure firmness throughout its useful life, Alapont Logistics folding lip levelers are equipped with 10 reinforcement beams that support the platform, providing them with greater strength and durability. In addition, in the area of the hinged lip, one of the areas exposed to the greatest wear, it incorporates reinforced steel hinges.

Maximum Safety

Exclusive features help prevent rapid free-fall, vacant dock drop-off, Stump-out, threats during maintenance, and more!

Express delivery time

Thanks to our permanent stock availability, we are able to offer exceptional delivery times.

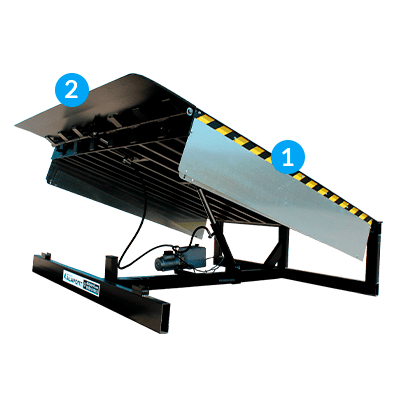

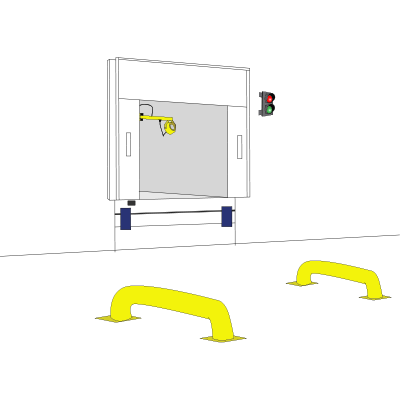

Components of the Hinge lip dock leveller for loading dock

The dock leveler is one of the most important dock equipment. Thanks to this, and through it, loading and unloading operations are carried out, bridging the differences in level between the warehouse and the vehicle. But what parts make it up? Next we are going to scrap the standard loading dock hydraulic ramp.

1. Surface platform

It is the surface of the dock leveler, made up of a single piece, made of tear-shaped sheet steel and treated with an anti-corrosion system. Alapont Logistics levelers are especially characterized by their internal reinforcements, which have 10 beams that support the platform, thus giving the dock greater strength and durability. Thus avoiding deformations on the surface after the continuous passage of vehicles.

1. Bridge deck.

2. Hinged Lip.

2. Hinged Lip

This is the second piece that makes up the surface of the hydraulic ramp. This piece, also called a nail due to its angled finish, overcomes the small distances and unevenness between the dock and the vehicle platform.

3. Structure

It is made up of a steel structure, attached to the dock pit, and which supports the surface of the loading ramp. It contains the entire system that allows the elevation of the surface. Some of these elements are: lifting cylinders, frame, pre-frame, retainer, springs, maintenance strut, etc.

4. Hydraulic group

Alapont Logistics hydraulic levelers have a 1.1 Kw (1.5 CV-380 Volt triphasic) motorization system and a slow fall control of the spring, in the event of the truck leaving.

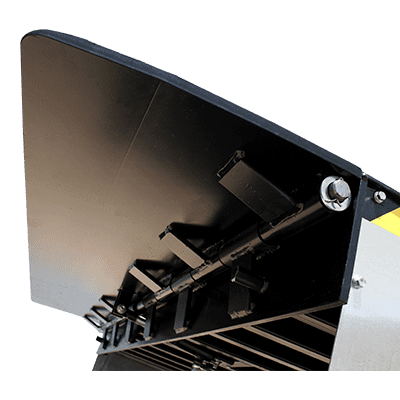

5. Deck and lip cylinders

Deck and lip cylinders provide the best in class operation. Full range at the touch of a button.

6. Security Toe Guards

Reduce the risk of foot-related injuries at the loading dock.

All these components are specifically designed to guarantee the durability and resistance of the dock leveller. Each one of them plays a primary role at the time of loading or unloading the truck.

Contact us

Newsletter Sign up

Sign Up for updates & promotions!

Categories

Dock Levelers

Vehicle restraints

Seals and shelters

Scissor lift tables

Accessories